HAVE YOU SEEN TIP TIG? THIS PROCESS PROVIDES LESS WELD HEAT AND BETTER

WELD QUALITY THAN TIG AND PROVIDES THOSE WELDS AT MIG WIRE FEED RATES.

MIG Gas facts and Weld Gas Tips.

The sad influence of

salesmanship & MIG Gas Selection?

"On the subject of salesmanship and MIG gas mixes, a MIG

weld lie told often enough will eventually become the welding truth"

MIG WELDING GAS SELECTION IN

MANY GLOBAL FACILITIES, HAS BEEN INFLUENCED

BY MARKETING HYPE AND LIES FROM THE MAJOR GAS COMPANIES AND WELD PROCESS IGNORANCE FROM WELD GAS DISTRIBUTORS AND THEIR CUSTOMERS.

Ed Craig 1990:

BY MARKETING HYPE AND LIES FROM THE MAJOR GAS COMPANIES AND WELD PROCESS IGNORANCE FROM WELD GAS DISTRIBUTORS AND THEIR CUSTOMERS.

Ed Craig 1990:

A MIG Weld Gas Reality: In a thirty minute practical weld demonstration, I could demonstrate that all the over priced, global three part gas mixes used for MIG welding carbon steels and stainless applications, will provide no practical weld quality, metallurgical or weld production benefits.

Please note this is a subject I have extensive expertise with. I was a key committee member that wrote the AWS A5.32 MIG - TIG

Shielding Gas specifications.

Shielding Gas specifications.As many of the AWS specification committees are made up of individuals that influence marketing decisions in their weld equipment / consumable manufacturing companies, a good portion of my efforts at the AWS gas spec meetings was trying to minimize the marketing sales hype that some of the gas committee members wanted to introduce into the MIG gas specification.

At the AWS gas specification meetings, exaggerated claims about a specific companies three part wonder gas would be discussed each time the committee got together. Three part and even four part MIG gas mix suggestions were in abundance. I was not completely successful in my quest for a none product biased AWS MIG gas specification, however over time I did eliminate an enormous amount of gas flatulence and gas mix product bias from the AWS MIG gas specifications.

In the weld gas business, you are never more than

one arms length away from sales BS.

Ed during a time out at an AWS MIG

gas

Specification Committee meeting in the 1993.

Specification Committee meeting in the 1993.

Weld shops take note: From the global, industrial gas confusion

comes the opportunity for increased gas profits.

I should know a little about MIG gas sales bias and customer product ignorance, I worked in the industrial gas business as a training or product manager for Praxair (Linde), Liquid Carbonic, Air Gas, and AGA.

Immerse a low cost commodity like industrial welding gases in lies, ignorance, sales hype and general weld shop confusion and you will increase your customer base and attain higher prices. Gases are really fun to learn about.

What

do you know about MIG gas mixes?

Why not try the MIG gas test

The MIG Welding Gas Test:

STAINLESS MIG WELDING. THE HELIUM TRI GAS

MIX

AND WELD REALITY:

2000: In the last three decades the

biggest selling gas mix in North America for MIG, stainless gage applications,

has been a helium tri mix gas containing

90 helium - 7.5 argon and 2.5% CO2.

The weld reality was this costly, Helium tri-mix was unnecessary for most thin gauge applications and this gas mix was the cause of many MIG stainless gage welding issues.

90 helium - 7.5 argon and 2.5% CO2.

The weld reality was this costly, Helium tri-mix was unnecessary for most thin gauge applications and this gas mix was the cause of many MIG stainless gage welding issues.

In the 1980s, Ed developed a MIG Gas Solution

for stainless. and duplex, 98% Ar - 2% CO2.

To confuse the weld industry

he called

his simple 2 component gas mix. STAIN MIX.

During the nineteen eighties, I carried out extensive, stainless MIG gas weld research for a company called AGA. When I examined the common denominators of the weld issues that occurred with MIG short circuit, on stainless thin gage welds, I found three primary weld issues that were prominent with the MIG process.

Weld issue 1. "Distortion"

Weld issue 2. "Oxidation"

Weld issue 3. "Burn through"

The common denominator of the three weld issues is "weld heat" and yet at that time in the late eighties, when welding thin gage stainless, for more than two decades the North American weld industry had been using the Helium Tri Mix, the world's hottest gas mix. The tri mix mix contained 90% He - 7.5% Ar - 2.5% CO2. The Helium Tri-Mix was developed by Union Carbide. What most people don't realize is that the Union Carbide research people developed this gas mix for short circuit on gage parts > 0.100. In the control of weld heat related issues, it's illogical to use the world's hottest gas mix.

As with many weld research subjects, all the weld options were not included and the Union Carbide helium tri gas research was not complete. The gas research that introduced the helium tri mix for the thicker gage welds, did not include using low end spray transfer on the > 2.5 mm gage parts they used to test the tri-mix gas. Even in the nineteen sixties, all the weld personnel had to do when MIG welding thick gage parts, was simply use a two part gas mix and an 0.035 wire, then change the MIG parameters to low spray transfer settings. Without the use of helium, the spray mode would provide all the energy required for the welds. However In 1968 as in 2010 the majority of weld personnel would not have known the low spray parameters required for stainless gage welds in the 2 to 3 mm range.

The argon - 2% CO2 mix is ideal for all stainless short circuit welds using 0.035 wires and welding gages <2.5mm. For welding thicker gages, these welds should be made with the same gas using pulsed with 0.045 wires, or low spray with 0.035 wires.

MIG Welding Gas Feedback

E-mail:Hello Mr. Craig.

I would like to thank you for the excellent information on your website, I'm a 4th year welding engineering student at Penn College of Technology. I'm currently knee deep in my internship. With the help of your information I was able to convince management to switch from the helium tri-mix to 98-2 argon-CO2 mix for 300 series stainless steel MIG welds, I'm also currently running tests to demonstrate that running 100% CO2 is probably not the most economical situation for structural steel welds (3/16 angle iron). Thank you again for all the information on your site, I've been introducing welding process control and theory information to increase efficiency both in engineering and fabrication. joel.ifill@spx.com

Ed's Mix. 98% Argon - 2% CO2.

Stainless / Duplex Short Circuit Weld Benefits:

Stainless / Duplex Short Circuit Weld Benefits:

Argon - 2% CO2 benefits on "gage parts": In contrast to the higher energy and higher voltages required from a 90% helium 7.5%% Ar - 2.5% CO2 tri-mix, the much lower cost and more gas in the cylinder, argon - 2% CO2 mix, will when short circuit or pulsed welding thin gage (<2.5 mm) stainless;

[a] reduce weld burn through potential,

[b] reduce weld distortion potential,

[c] reduce weld oxidation potential,

[d] reduce the potential for all forms of weld cracking.

[e] reduce volt requirements more comfortable for the welder,

[f] reduce stainless weld fumes,

NEXT STEP ELIMINATE 98 ARGON 2 OXYGEN FOR SPRAY: After I finished my gas research on stainless gage parts, I then turned my gas research attention to MIG spray transfer on thicker stainless applications which for a few decades were typically MIG welded with the common 98% Ar - 2% oxygen mix. Please remember in the early eighties we did not have pulsed equipment that worked for two days in a row without doing something weird.

Ed's Mix. 98% Argon - 2% CO2.

Stainless / Duplex.

Pulsed and Spray Weld Benefits:

Pulsed and Spray Weld Benefits:

SPRAY and PULSED. STAINLESS STEEL / DUPLEX APPLICATIONS:

For more than four decades in North America, argon 2 to 5% oxygen were the most common MIG gas mixes sold for welding stainless steel spray applications. For MIG welding stainless alloys which should be "protected from an oxygen atmosphere", the argon oxygen mixes were and still are a poor choice.

For MIG welding > 3 mm stainless welds, I examined the differences between my low oxidizing argon - 2% CO2 mix and the traditional argon 2 - 5 % oxygen mixes commonly used for spray and pulsed MIG applications.

( Note: It's important to remember that one percent oxygen is approx. ten time more oxidizing than one percent CO2.)

Argon - 2% oxygen Spray fillet

on 304 Stainless:

Nov 2008: For decades and still today, MIG Gas manufacturers and distributors recommend

argon - oxy mixes for stainless spray and pulsed applications. If you want to part of the real weld world and reduce the oxidation potential and produce cleaner spray and pulsed MIG stainless welds, try my argon 2% CO2 mix, by the way it's only been available for twenty years.

ARGON 2% CO2 SPRAY / PULSED BENEFITS:

In contrast to the traditional argon - oxy mixes, an

argon 2 % CO2 mix results in cleaner, (less oxidized) welds on stainless spray or pulsed spray applications. The weld oxide reduction from the argon 2 CO2 mix is especially notable when welding parts > 4 mm.

ARGON 2% CO2 SPRAY / PULSED BENEFITS: In contrast to argon - oxy mixes, the

argon 2% CO2 mix is very beneficial on multipass stainless welds. With multipass welds the build up of oxidation elements and surface slags can result in excess weld porosity or unnaceptable inclusions. The argon 2% CO2 mix is a logical choice for MIG short circuit, pulsed or spray welds on food industry applications in which the weld surface cleanliness is important.

Note: In contrast to argon oxy mixes, when using an argon - 2% CO2 mix, on spray or pulsed applications, > 4 mm thick, you can expect cleaner welds, however when welding thinner gages keep in mind that most of the black or gray weld surface oxidation is occurring from the reaction of heated thin parts and the parts reaction with the oxygen in the atmosphere.

argon 2 % CO2 mix results in cleaner, (less oxidized) welds on stainless spray or pulsed spray applications. The weld oxide reduction from the argon 2 CO2 mix is especially notable when welding parts > 4 mm.

ARGON 2% CO2 SPRAY / PULSED BENEFITS: In contrast to argon - oxy mixes, the

argon 2% CO2 mix is very beneficial on multipass stainless welds. With multipass welds the build up of oxidation elements and surface slags can result in excess weld porosity or unnaceptable inclusions. The argon 2% CO2 mix is a logical choice for MIG short circuit, pulsed or spray welds on food industry applications in which the weld surface cleanliness is important.

Note: In contrast to argon oxy mixes, when using an argon - 2% CO2 mix, on spray or pulsed applications, > 4 mm thick, you can expect cleaner welds, however when welding thinner gages keep in mind that most of the black or gray weld surface oxidation is occurring from the reaction of heated thin parts and the parts reaction with the oxygen in the atmosphere.

2008: It's taken more than 20 years, but today some gas companies, consumable and weld equipment manufacturers like Miller are now recommending my argon 2% CO2 mix for stainless

or duplex alloys.

THE CO2 CONTENT INFLUENCE ON CARBON PICKUP

IN LOW CARBON STAINLESS ELECTRODES:

What's good for the

welding goose should be good for the welding gander. An important weld issue

neglected by the suppliers of electrodes and the person who provide weld

specifications is an issue which should have a great influence on the so called

acceptance level of CO2 in a MIG gas when used for welding "L" grade

stainless.

What's good for the

welding goose should be good for the welding gander. An important weld issue

neglected by the suppliers of electrodes and the person who provide weld

specifications is an issue which should have a great influence on the so called

acceptance level of CO2 in a MIG gas when used for welding "L" grade

stainless.While engineers worry about the influence of CO2 on the carbon content of a stainless weld, they allow the stick process (SMAW), low carbon stainless electrodes to have a higher level of carbon content than the equivalent MIG electrode wires.

I believe it's difficult for the manufacturers of low carbon stainless SMAW electrodes to get the carbon to levels <0.030%, which is the amount specified for the low carbon stainless MIG wires. However this electrode chemistry flexibility creates a ridiculous double standard from stainless weld consumable manufacturers, and from an engineering perspective its simply unacceptable. My argon - 2% CO2 mix does not change the carbon content of a weld made with a low carbon electrode

USA 1990s: Ed developed these three gas mixes which were optimum

for the majority of all steel, stainless and aluminum applications.

Note Ed's simple gas marketing approach which indicated

to the customers, what the MIG gas cylinders should be used for, this was a first in the global gas industry.

to the customers, what the MIG gas cylinders should be used for, this was a first in the global gas industry.

When that new gas mix is wheeled into the weld shop, the weld

supervisor may pass the buck and say "let the welders test the mix".

Ask ten welders including the weld supervisor, the weld parameter difference between an argon 20% CO2 mix and an argon 2% oxygen mix and you will get a glazed look from 20 eyes and 10 different answers.

Should weld decision makers

understand MIG weld

gas mixes. Why not try this MIG Weld Gas Test:

gas mixes. Why not try this MIG Weld Gas Test:

MIG Welding Gas Reality Check.

That new MIG gas mix wheeled

into the weld shop every six months is often viewed as the crutch that will

hopefully be the solution to the many MIG issues that daily occur in the shop.

With MIG welding, there simply is no reason to try a new gas once a month or for

gas confusion.

You will never need more than a two component argon CO2 gas mix for all short circuit, spray and pulsed spray applications on the majority of carbon steels, low alloy steels, nickel alloys and stainless steels.

A two component, argon CO2 mix, used with the correct MIG data and consumables, can provide the highest weld productivity and meet the weld mechanical, property requirements of the most stringent ASTM / ASME / API weld specifications.

You will never need more than a two component argon CO2 gas mix for all short circuit, spray and pulsed spray applications on the majority of carbon steels, low alloy steels, nickel alloys and stainless steels.

A two component, argon CO2 mix, used with the correct MIG data and consumables, can provide the highest weld productivity and meet the weld mechanical, property requirements of the most stringent ASTM / ASME / API weld specifications.

Carbon Steels and MIG Gas Selection:

Spray transfer occurs on steels

and stainless applications with specific argon mixes and minimum, narrow weld

parameter range. You have achieved spray when weld droplets smaller than the

wire diameter or a weld stream cascades across an open arc. Depending on the

spray transfer weld parameters used, the weld stream could also be a combination

of both weld drops and stream.

Pulsed Spray transfer occurs on

steels and stainless with straight argon or argon mixes and specific, wide range

of pulsed weld parameters. You have achieved controlled pulsed when weld

droplets smaller than the wire diameter cascade, uninterrupted (a rareity)

across an open arc.

Spray Transfer MIG Gas Myth.

If you had been around weld

shops in the 1980s - 1990s perhaps you read an erroneous MIG gas statement

somewhere that states, "you cannot get spray transfer with an argon - 15 to 25%

CO2 gas mix"

1990: Weld Reality Fact. For

thirty plus years, Lincoln, Miller, BOC,Hobart, Liquid Air, Air Products, Liquid

Carbonic and almost everyone else in North America who made MIG welding

equipment, consumables and weld gases, all stated in either their weld books or

promotional MIG literature, "that you could not get MIG spray transfer on carbon

steel welds with using more than 10 or 15% CO2 with any MIG electrode

diameter.

The so called welding experts at these large weld equipment and consumable companies must have never worn a welding shield when evaluating the spray transfer mode. The weld reality is if you know what you are doing, with specific wire diameters, you can get spatter free spray transfer welds with argon - 25% CO2, however why use this mix when lower CO2 provides superior transfer at more manageable weld parameters.

MIG Gas Fact: Any global weld shop that uses the 75 Ar - 25% CO2

mix, is a weld shop without weld management.

The so called welding experts at these large weld equipment and consumable companies must have never worn a welding shield when evaluating the spray transfer mode. The weld reality is if you know what you are doing, with specific wire diameters, you can get spatter free spray transfer welds with argon - 25% CO2, however why use this mix when lower CO2 provides superior transfer at more manageable weld parameters.

MIG Gas Fact: Any global weld shop that uses the 75 Ar - 25% CO2

mix, is a weld shop without weld management.

For those who

doubt that with an argon mix containing 25% CO2, spray transfer is not

attainable why not put on a welding shield, after all seeing is

believing.

For those who

doubt that with an argon mix containing 25% CO2, spray transfer is not

attainable why not put on a welding shield, after all seeing is

believing.For this MIG gas test, the object is produce a 1/4, 6 mm fillet weld on >3/8 (>9mm) plate. Using a 350 amp power source or larger. Set an "0.045 (1.2mm)" MIG wire feed rate at 450 in./min (11.4m/min), or place your none digital wire feed control at the 2 o'clock position. Important, to attain spray transfer with 25% CO2, you will require a higher than normal spray transfer weld voltage, typically 32 to 36 volts is required, (make sure the power source has this capability). The high weld voltages required for the spray mode with the 25% CO2 will produce spray transfer in which the weld droplets and stream are smaller than the wire diameter.

The prime negative attribute of using argon - 25% CO2, is the high amount of CO2 provides high energy and requires high weld voltages. The resulting high arc heat and weld heat can be uncomfortable for welders. Also with 25% CO2, the high weld fluidity that results may cause issues such as undercut or poor weld puddle control on specific welds.

Note: With an 0.035 (1 mm) MIG wire, consistent spray transfer "is not attainable with argon - 25% CO2". Spray transfer is however attainable with the 0.035 wire when using argon mixes with < 20% CO2.

THE BOTTOM LINE IS THERE IS NO NEED FOR ANY WELD SHOP TO USE THE 75 ARGON - 25% CO2 GAS MIX, AS THIS POPULAR GAS MIX HAS ALWAYS PROVIDED LESS THAN OPTIMUM WELD RESULTS FOR MOST OF THE COMMON MIG WELD APPLICATIONS.

Reducing the CO2 gas content in an argon

mix to a maximum of 20% for carbon steel welds, brings the transition current

down and also brings the required spray welding voltages down to comfortable

weld levels in which 25 to 32 weld volts for spray transfer with 0.035 - 0.045

(1 - 1.2 mm) wires is typical.

Reducing the CO2 gas content in an argon

mix to a maximum of 20% for carbon steel welds, brings the transition current

down and also brings the required spray welding voltages down to comfortable

weld levels in which 25 to 32 weld volts for spray transfer with 0.035 - 0.045

(1 - 1.2 mm) wires is typical.1988 or 2008. When will the

MIG weld industry grow up?

When confusion reigns in a welding shop, everyone typically looks for a quick solution and in comes that salesman with the magician's approach to weld problems that would not occur if the weld shop had management or supervison weld process expertise.

In the last few decades, you did not have to look far to find a gas sales rep, ready to introduce you to his companies new 3 part MIG gas mix and in 2010, what's changed?

The next picture is a gas company advertisement in a welding magazine.

The gas company wants to believe that it's "MIG gas mixes are special"

and will provide your organization with special weld benefits.

Take that cape off the cylinder, get

rid of the Sales Bovine Fecal Matter

and any MIG gas mix should simply be a low cost commodity.

and any MIG gas mix should simply be a low cost commodity.

Providing that so

called "unique" three part gas mix for carbon steel and stainless welds enables

the gas manufactures and distributors to dream up glossy brochures which enable

them to attain new MIG gas accounts and generate higher gas prices and profits

on what should be low cost commodity products.

Providing that so

called "unique" three part gas mix for carbon steel and stainless welds enables

the gas manufactures and distributors to dream up glossy brochures which enable

them to attain new MIG gas accounts and generate higher gas prices and profits

on what should be low cost commodity products.

Build a gas plant and bingo you

have access to the world's greatest free commodity "air" All the argon, oxygen

and nitrogen you will ever need pulled out of the atmosphere at very low costs.

All you then need is a a distribution system, a marketing manager, glossy

brochures full of unfounded or exaggerated weld claims, add a few salesmen into

the pot and then direct them to find thousands of gullible weld customers who

will pay a premium for the three or four part gas mixes.

Gas company executives love annual bonuses and share holders need to see growth, so each year, the pressure is on the gas marketing guru to invent unique MIG gas feature benefits, or come up with a new three or four part gas mix to justify the higher gas prices charged.

THAT NEW GAS MIX

Carbon Steels and MIG

Tri-Mix Gas Facts.

GAS SALES HAVE DONE THEIR JOB:

For the last two decades, one the most widely marketed gas mixes promoted in

North America for MIG welding carbon steels, is a tri-mix containing

argon - 5 - 10% CO2 and 1-2% O2.

argon - 5 - 10% CO2 and 1-2% O2.

3 Part Gas Mixes and Weld Reality.

Up to the end of the nineteen

eighties, the industrial gas marketing and sales focus was placed on converting

straight CO2 users to more cost effective argon mixes. With the competition for

the highly profitable gas business, the two part mixes quickly turned to three

part and four part mixes.

Fact: Every three and four part mix ever sold for MIG welding carbon steels and stainless offers nothing that cannot be achieved with two part gas mixes and a little MIG weld process control expertise.

In contrast to the lower cost, two part argon CO2 mixes, the three part argon - CO2 - oxy mixes used for carbon steels, offer "no practical weld benefits that can be measured" in terms of weld quality, weld metallurgy or weld productivity.

Have you noticed since the introduction of three part MIG gas mixes, the lack of welding articles on this subject. Have you also noted that when some one does write an article on the cloudy, MIG weld gas subject, the author typically represent the gas company that's trying to promote the

Fact: Every three and four part mix ever sold for MIG welding carbon steels and stainless offers nothing that cannot be achieved with two part gas mixes and a little MIG weld process control expertise.

In contrast to the lower cost, two part argon CO2 mixes, the three part argon - CO2 - oxy mixes used for carbon steels, offer "no practical weld benefits that can be measured" in terms of weld quality, weld metallurgy or weld productivity.

Have you noticed since the introduction of three part MIG gas mixes, the lack of welding articles on this subject. Have you also noted that when some one does write an article on the cloudy, MIG weld gas subject, the author typically represent the gas company that's trying to promote the

three part mystery gas product.

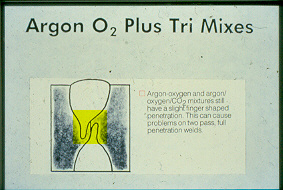

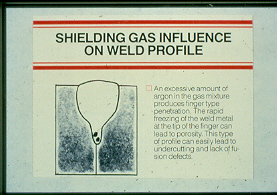

The gas reality of adding

Oxygen to Argon CO2. Thanks to process ignorance in weld shops, gas marketing

lies and salesmen that lack weld process expertise, three part mixes containing

argon / CO2 / Oxy are huge sellers in North America. If you take an argon CO2

mix and add oxygen to that mix, you simply "increase the weld oxidation

potential" and lower the unique weld energy potential .

The

oxygen addition in the three part gas mixes will influence the weld root fusion

profile. When you add oxy typically a narrow finger penetration profile is

produced, influenced by the lower energy narrow plasma, and lower weld energy

.

The

oxygen addition in the three part gas mixes will influence the weld root fusion

profile. When you add oxy typically a narrow finger penetration profile is

produced, influenced by the lower energy narrow plasma, and lower weld energy

. The narrow finger fusion weld profile freezes rapidly trapping the

oxygen gas oxide reactions, increasing the weld porosity potential. Remember a

primary purpose of a gas mix is to prevent oxygen and nitrogen from entering the

welds.

The narrow finger fusion weld profile freezes rapidly trapping the

oxygen gas oxide reactions, increasing the weld porosity potential. Remember a

primary purpose of a gas mix is to prevent oxygen and nitrogen from entering the

welds.  2008" Apart from the 40 years that I have evaluated MIG gas mixes,

perhaps you would like another point of view. Back in the nineteen sixties, the

British Welding Institute, (at that time an unbiased research organization),

carried out MIG gas research. The MIG gas research indicated in contrast to

argon mixes with 5 to 20% CO2, three component gas mixes containing argon - CO2

- oxygen when used for welding carbon steels "provided no practical weld

benefits". The conclusion, when adding oxygen to an argon CO2 mix simply lowers

the weld energy lowering the weld fusion potential increasing weld porosity

potential.

2008" Apart from the 40 years that I have evaluated MIG gas mixes,

perhaps you would like another point of view. Back in the nineteen sixties, the

British Welding Institute, (at that time an unbiased research organization),

carried out MIG gas research. The MIG gas research indicated in contrast to

argon mixes with 5 to 20% CO2, three component gas mixes containing argon - CO2

- oxygen when used for welding carbon steels "provided no practical weld

benefits". The conclusion, when adding oxygen to an argon CO2 mix simply lowers

the weld energy lowering the weld fusion potential increasing weld porosity

potential. Tri Mix Welding gas cost facts your

welding distributor may not tell you:

2008: ONE OF THE BIGGEST SELLING MIG

GAS MIXES IN NORTH AMERICA FOR MIG WELDING CARBON STEELS, IS A THREE PART MIG

GAS MIX CONTAINING

ARGON - CO2. 5-10% - OXY. 1-2%.

ARGON - CO2. 5-10% - OXY. 1-2%.

GAS COSTS: A THREE PART GAS MIX TYPICALLY COSTS 20 TO 50% MORE THAN A TWO COMPONENT ARGON - CO2 MIX.

LESS GAS: THE THREE PART MIG GAS MIXES WILL HAVE LESS GAS IN THE CYLINDER THAN A TWO PART ARGON CO2 MIX. IN CONTRAST, THE CO2 CYLINDER MIX WILL KEEP YOU RUNNING FOR AN ADDITIONAL ONE HOUR ARC TIME

LESS WELD INTEGRITY: THE THREE PART MIXES ARE MORE OXIDIZING THAN ARGON CO2 INCREASING POROSITY POTENTIAL, DECREASING SIDE WALL WELD FUSION AND PROVIDING LOWER IMPACT PROPERTIES. THE THREE PART GAS MIXES TYPICALLY PRODUCE INFERIOR WELD FUSION, (FINGER) PENETRATION. FINGER PENETRATION LEADS TO A NARROW ROOT BAND IN WHICH THE WELD ROOT FREEZES SO RAPIDLY THAT GAS PORES MAY NOT HAVE TIME TO ESCAPE.

LESS PERFORMANCE: THE THREE PART MIX IS MORE SENSITIVE TO WIRE STICK OUT CHANGES, MILL SCALE, COATINGS OR SURFACE CONTAMINATES. AS THE THREE PART MIX WILL TYPICALLY REQUIRE LOWER VOLTAGE, (THANKS TO THE OXY) THESE MIXES HAVE LESS ARC STABILITY WITH MANY HIGH DEPOSITION / HIGH WELD SPEED APPLICATIONS.

If you still believe a 3 part gas mix is necessary for welding

carbon steels give me a call, I am looking for investors to buy a boat business

in the middle of Kansas. If you need more convincing my 600 page "Management

Guide To MIG" book has more than 100

pages on MIG Gas Reality for all applications.

If you still believe a 3 part gas mix is necessary for welding

carbon steels give me a call, I am looking for investors to buy a boat business

in the middle of Kansas. If you need more convincing my 600 page "Management

Guide To MIG" book has more than 100

pages on MIG Gas Reality for all applications. If the world's supply of oxygen was lost to the welding industry

tomorrow, it would have zero impact on MIG

welding.

The weld reality. In the MIG welding industry there has never been a need for MIG gas mixes that contain oxygen, however their has always been a great need for industrial gas companies to sell their abundant supply of oxygen and increase their gas margins through the sale of three part gas mixes containing oxy. E. Craig 1991.

2007: ED'S MIG GAS SELECTION.

SIX MIXES FOR THE MAJORITY OF MIG APPLICATIONS.

SIX MIXES FOR THE MAJORITY OF MIG APPLICATIONS.

Ed's Mix. 85% Argon - 15% CO2.

Carbon and low alloy steel applications.

Argon - 15% CO2:

Argon - 15% CO2: A MULTIPURPOSE GAS MIX FOR MIG / FLUX CORED. CARBON

AND LOW ALLOY STEEL APPLICATIONS:

Applications: Great multipurpose MIG gas mix: Use with short circuit, spray, pulsed spray modes. Also for "all position" flux cored welds on carbon steels, low alloy steels, stainless, Inconel and duplex.

From the nineteen seventies to the early nineteen nineties, argon CO2 MIG mixes were few. The most popular two mixes were argon - 8 % CO2 and argon - 25% CO2.

Argon - 20% CO2 was a common mix sold in Europe before it was introduced by AGA in the US. Today argon 20% CO2 is a common mix, however it's not uncommon with some distributors to get more of the lower cost CO2 than you ask for in the cylinder and many of the 20% CO2 mixes end up with > 25% CO2.

In the early 1980s while with AGA I introduced a logical gas mix Argon - 15% CO2. This CO2 content allowed for less opportunity for the MIG gas contents to go over 23% CO2 which affects the formation of spray transfer with an 0.035 (1mm wire. In contrast to argon - 20% CO2. This gas mix enables a slightly lower weld voltage and provides improved weld puddle control with spray applications.

An argon - 15% CO2 mix is without question the best "high energy, multipurpose gas mix" for most job shops, structural steel shops, heavy fabrication shops, pressure vessel or any shops that manual MIG and flux cored weld carbon steel plate thicker than 1/4 (>6mm).

The argon 15% CO2 mix is superior to argon - 10% CO2 when spray transfer is used on steels that have mill scale, primers, surface contaminates and galvanealed, galvanized / coatings.

In contrast to argon - 25% CO2 which cannot provide spray with an 0.035 wire, the argon - 15% CO2 gas mix provides stable spray.

With short circuit on gage applications < 2 mm, the argon - 15% CO2 gas mix is superior to argon 25% CO2 as it can reduce weld burn - through potential.

The argon 15% CO2 gas mix provides optimum weld results when used with all position welds using gas shielded flux cored electrodes welding carbon steels, low alloy steels, stainless, duplex and Inconel.

The argon 15% CO2 mix is also beneficial for robot or mechanized "high speed" welds on metals

> 4mm. In contrast to three part mixes containing argon - CO2 - oxygen, argon oxygen mixes or argon <15% CO2 mixes, the higher voltages required for this mix and the higher dissociation (HIGH ENERGY) properties of CO2 assist in stabilizing the arc and provide superior weld penetration.

Argon 10% CO2.

Argon 10% CO2.PULSED MIG STEEL:

Compatible mix range. CO2. 8 - 12%.

Applications: Best low energy MIG gas mix for spray and or "pulsed" carbon steel and low alloy steels welds on < 7 mm components. On many robot or manual carbon steel welded parts, the weld heat from high wire feed spray or pulsed welds can cause, distortion, weld burn through or excess weld fluidity causing weld undercut or oxidation. The fact that this gas provides lower energy than higher CO2 mixes makes it beneficial for these applications.

What is really interesting about this medium energy gas mix is that its also the best choice for welding thick steels as long as the mill scale and other surface contaminates are removed.

When spray transfer welding horizontal fillets larger than 6 mm, or multi-pass fillet welds in which the weld heat buildup is notable, the welder is aware of the high weld fluidity. Weld fluidity increases as the CO2 content of the gas increases. Argon with 15 or 20% CO2 produces welds with more fluidity than argon with 10% CO2. So if you want improved weld control remember this point.

With this same logic, if you are using the 10% CO2 mix with the pulsed / spray process on steels > 6 mm thick and you need more weld fusion , change the gas to a higher CO2 mix such as 15 - 20% CO2 mix.

Ed's Mix. 98% Argon - 2% CO2.

Argon - 2% CO2.

Argon - 2% CO2. STAINLESS and DUPLEX APPLICATIONS:.

Composition Range. 1.5 - 2.5% CO2.

I developed this unique stainless MIG gas mix while at AGA in the nineteen eighties. This very low oxidizing mix is suited for all MIG short circuit, spray and pulsed on all stainless / duplex weld and clad applications.

I would also recommend this mix for anyone MIG welding very thin carbon steel and low alloy steels, gauges < 0.040. Do not use this mix with any flux cored wires or with GTAW applications.

When welding stainless short circuit applications, forget the common, more costly 90 helium - 7.5 argon - 2.5 CO2 tri mix, a premium priced gas mix that the major gas suppliers love to sell, instead use this lower cost, more effective argon 2% CO2 mixes.

COMPARE WITH HELIUM TRI- MIX? In

contrast to the more costly, higher energy, helium tri-mix, the argon - 2% CO2

mix when used on thin gage applications can provide;

[1] less part distortion,

[2] less weld burn through potential,

[3] less contact tip issues,

[4] improved arc stability,

[5] lower cost gas,

[6] more gas in the cylinders,

[7] less opportunity for stress corrosion cracks, hot crack, and micro cracks.

COMPARE WITH ARGON - OXYGEN MIX? In contrast to the argon oxygen MIG mix recommended by all the gas companies for stainless spray and pulsed applications, my argon 2% CO2 mix can result in less oxidized, cleaner MIG spray or pulsed welds with less weld porosity potential.

Note: When used for "low carbon" stainless applications, the carbon content in the weld will be acceptable with this low CO2 gas mix for all short circuit, pulsed and spray stainless applications.

Ed's Mix. 98% Argon - 2% CO2 - 1 % Nitrogen.

[1] less part distortion,

[2] less weld burn through potential,

[3] less contact tip issues,

[4] improved arc stability,

[5] lower cost gas,

[6] more gas in the cylinders,

[7] less opportunity for stress corrosion cracks, hot crack, and micro cracks.

COMPARE WITH ARGON - OXYGEN MIX? In contrast to the argon oxygen MIG mix recommended by all the gas companies for stainless spray and pulsed applications, my argon 2% CO2 mix can result in less oxidized, cleaner MIG spray or pulsed welds with less weld porosity potential.

Note: When used for "low carbon" stainless applications, the carbon content in the weld will be acceptable with this low CO2 gas mix for all short circuit, pulsed and spray stainless applications.

Ed's Mix. 98% Argon - 2% CO2 - 1 % Nitrogen.

Argon - 2% CO2 - 1%

Nitrogen.

Argon - 2% CO2 - 1%

Nitrogen.Mixing range. Nitrogen 0.75 to 1.75%

Suited to MIG Duplex Applications.

Mixing range. CO2 1.5 - 2.5%.

I developed this special MIG mix in the early nineteen nineties. On many duplex applications, the stainless gas argon 2% CO2 mix is sufficient. However if you need to increase your duplex mechanical MIG weld properties you should try this mix.

In many instances three part mixes are nothing more than a sales tool, however when MIG welding duplex, a touch of nitrogen in the MIG mix can be beneficial.

DUPLEX AND CO2 CONTENT: Again note the very low CO2 content, enough to stabilize without oxidation or carbon pick up concerns.

DUPLEX AND NITROGEN CONTENT: When added to a weld, a small amount of nitrogen can be a potent austenite stabilizer. The addition of nitrogen to the duplex weld / steel will promote structural hardening by a solid solution mechanism. The small nitrogen addition therefore can raise both the yield strength and ultimate strengths of the duplex without impairing toughness. The low CO2, combined with the benefits of low nitrogen content, truly make this gas mix unique.

This mix will also provide stable short circuit, pulsed and spray transfer. If you are using short circuit, STT or RMD for pipe roots, first try the stainless duplex gas listed above, (argon 2 CO2). If the Duplex root or fill pass weld mechanical properties need to be increased try this gas mix.

If more weld fluidity is need for pulsed MIG or spray transfer on fillet welds and pipe fill passes on those duplex applications welds, try the following gas mix recommended for the MIG Nickel applications

Using the flux cored wires for duplex, use the argon 18 - 25 % CO2 mixes.

It's beneficial with cylinders that contain very small amounts of a gas, if the cylinders contain dip tubes for complete gas mixing. I would order this gas mix through a specially gas supplier and ask for a certificate of composition compliance.

Ed's Mix. 59% Argon - 40% Helium - 1 % CO2.

Nickel Applications.

Argon - 40%Helium - 1% CO2:

Argon - 40%Helium - 1% CO2: Mix range. CO2. 0.75 to 1.5%.

Note: The low CO2 content must be carefully mixed and controlled. Order cylinders with dip tubes. Pay a little more and order from specially gas facility to ensure the mix is correct.

This is when you can benefit from a tri-mix. I developed this very unique mix in the nineteen eighties. How many of you have read in welding literature that when MIG welding nickel alloys, the gas mix cannot utilize a reactive component like oxygen or carbon dioxide. For decades this was another welding myth that had a negative impact on companies that MIG welded nickel alloy applications.

When using the recommended straight argon for Nickel applications with MIG spray or pulsed welds, the wire feed range was restricted, lack of weld fusion was common, and magnetic disruptions of the arc was a regular occurrence.

Being aware of the oxidation concerns with nickel welds and the benefits of low oxidizing CO2, I decided to try very small amounts of CO2 added to argon.The 1% CO2 did not oxidize the nickel welds and provided substantial weld benefits for MIG welding nickel alloys.

NICKEL AND CO2 CONTENT: When using straight argon, to maintain arc stability the wire feed rate was restricted. The 1% CO2 addition allows for increased arc stability through improved electron transfer without concern for oxidation contamination of the weld. The 1 % CO2 enabled higher wire feed rates which provided higher current capability improving weld fusion. The higher wire feed also allows higher automated / robot weld speeds and higher weld deposition rates for the nickel alloy welds. The 1% CO2 content also dramatically improved the weld fluidity of the sluggish nickel alloy welds improving the weld fusion potential.

Nickel alloys are sensitive to magnetic fields which disturb the MIG arc. The 1% CO2 assists in arc / electron stabilization, reducing the effects of magnetic disturbances and stabilizing the pulsed or spray weld transfer. After I stabilized the Nickel welds at higher than normal wire feed rates, I needed another gas addition to promote more weld energy for superior side wall fusion. I added helium.

HELIUM CONTENT: Some MIG gas mixes with 10 to 25% helium are recommended for Nickel alloy welds, however the weld effects are minimal. If you really want to add energy and fluidity to that weld, get the helium content up to 40%. Too much helium can add to the arc instability and also reduces the arc cleaning potential. As my 40% helium mix contains 1% CO2 you won't have to worry about the arc stability which is typically an issue with argon helium mixes.

You will pay more for my mix and possibly have to order it from

a company that provides special gas mixes, however with the increased wire feed

rate potential and superior weld fusion, you will reduce your weld labor costs

by at least 30% and dramatically reduce the weld rework required on those costly

nickel alloys.

This mix is also recommended for duplex applications in which

additional weld energy is required. More info on this gas mix and its use for

alloy welds is available in my Management Engineers guide to MIG book.

ALUMINUM MIG > 6 mm.

ALUMINUM MIG > 6 mm.Argon- 40% Helium.

Typically straight argon works well on many spray and pulsed aluminum applications. When MIG welding aluminum parts thicker than 6 mm and improved weld fusion or less weld porosity is required, the solution is additional weld energy. The addition of helium provides more weld energy. It's important not to put to much helium into the mix as you can reduce the arc stability and the cleaning action. The larger argon molecules and reverse polarity are responsible for the aluminum oxide removal, (cleaning action).

source:weldreality.com